*In order to protect customer’s privacy, we are not showing the photo of the final product.

This project has taken around 2-3 years (2020-2022).

In the covid epidemic era, world’s economic was once in chaos, prices for raw materials fluctuates significantly, industry manufacturing was facing unprecedented difficulties,

everything is hard, the project was forced to stop constantly for many reasons, but we never gave up on it. Fortunately, the struggle is finally worth it.

Below is the email we received from customer after solving a problem regarding product testing.

Below is the email when we finally received the order. (Customer informed us that they received the order from his client)

Below is the email we received from customer after sending the mass-production sample.

BRIEF OF THE CASE:

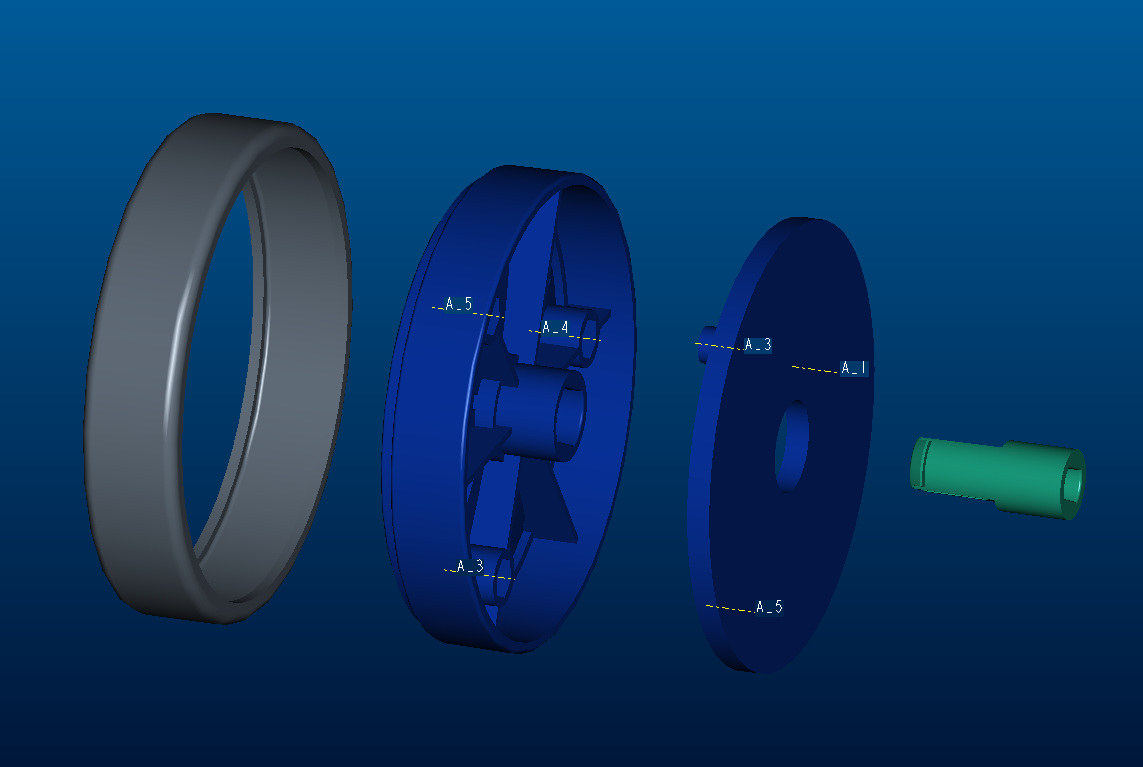

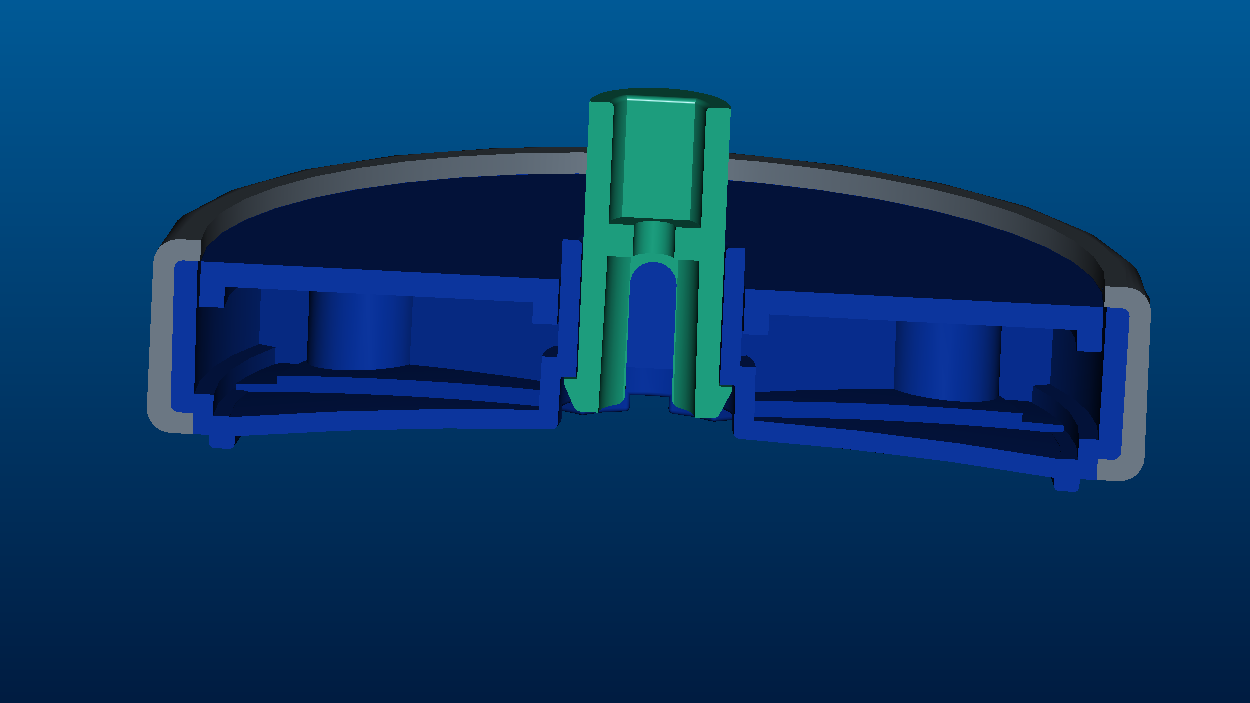

Client’s client has created a 3D file of an electric toy and needs to find a professional big factory to produce it.

The sales market is Germany, the testing standard (GS) for toys exporting to Germany is the strictest in the world, so client is very careful in choosing supplier.

They sent the inquiry to about 5 suppliers from China trying to find the best factory that is able to take the order.

After comprehensive evaluation, they chose 2 suppliers to make the mock-up samples to compete for the order, and we are one of them.

We are experienced in products’development, and we are good at making prototypes. We have most skilled engineer team.

By providing a nice prototype with function, we won the chance to make the mold.

In Jun 2022 we received the mould order.

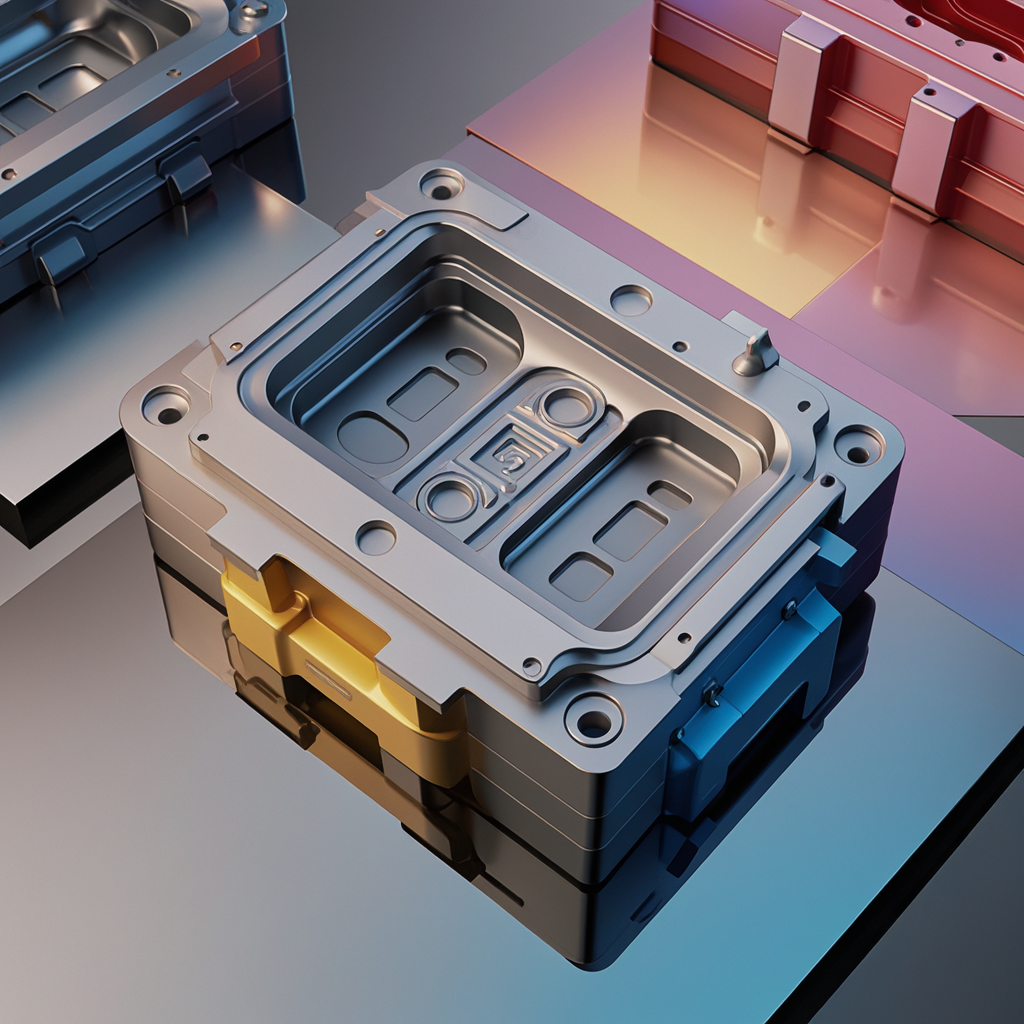

It took around 40 days for making the 16 sets of moulds of different parts of the toy.

2 weeks to adjust the mould and make the first sample out of the mold.

30 days for the lab to test the sample and give PRODUCT TESTING REPORTS and FACTORY AUDIT REPORTS

In April 2023, we finally received the PO of the formal order from client, the production went on smoothly and the goods were well delivered to client’s warehouse in June.